Dry microplasma equipment

Product Description

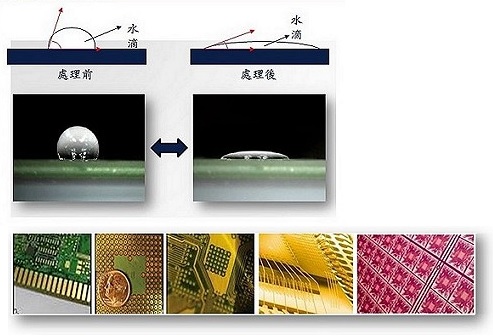

- Plasma dry etching(Desmear,Descum)

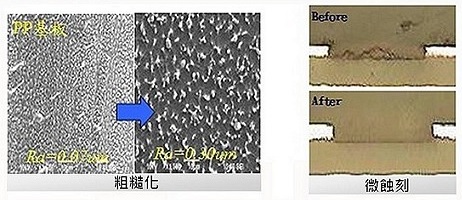

- Surface modification, roughening

- Etching material:PP,PMMA,ABF,Epoxy,…(All kinds of polymeric substance)

- substrate:Wafer, Si, Glass, PP, PMMA,Cu…(All kinds of substrate)

Equipment characteristic

- Multi-piece design

- High Capacity、Low revolution cost

- Chemica Reactive Ion Etching

- Not special gas demand

- Modulized design,Customization

- Substrate size:21” x 24”

Product application category

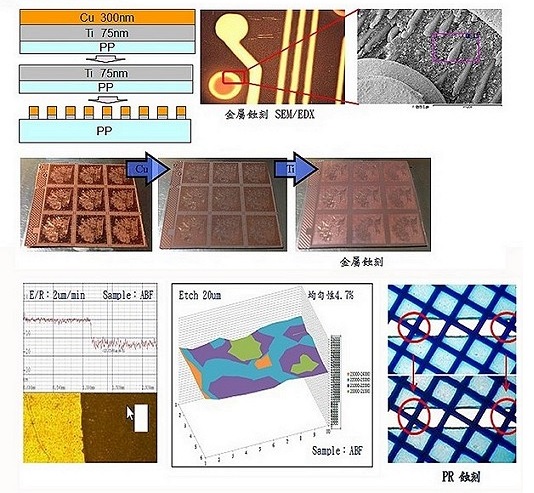

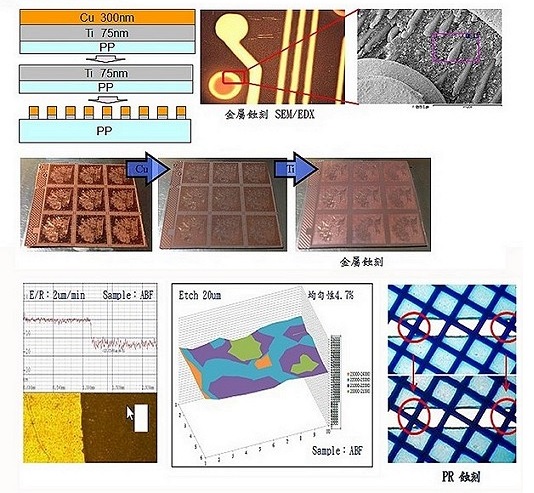

Metal plasma equipment/Equation plasma equipment

Product Description

- Plasma dry etching

- Etching material: Cu, Ti, Ta, Si, SiO2,Pd…(All kinds of metal)

- Etching material:PP,PR,PMMA,ABF,Epoxy…(All kinds of polymeric substance)

- substrate: Wafer, Si, Glass, PP, PMMA, Cu…(All kinds of substrate)

Equipment characteristic

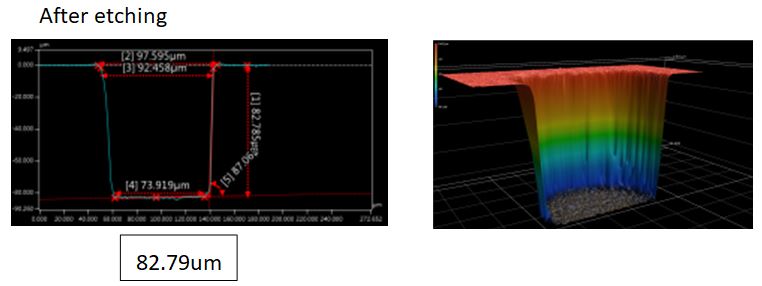

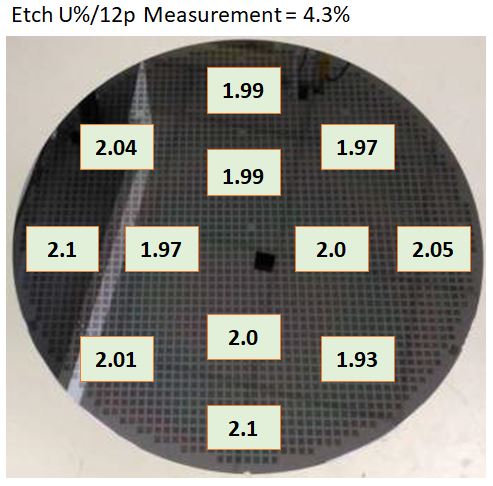

- High-speed dry etching process

- High cooling capacity,Low substrate deformation

- High aspect ratio etching direction(low side etching)

- High Capacity、Low revolution cost

- Modulized design,Customization

- Substrate size:4”, 6”, 8”,16” x 20”, 20” x 24”

Product application category

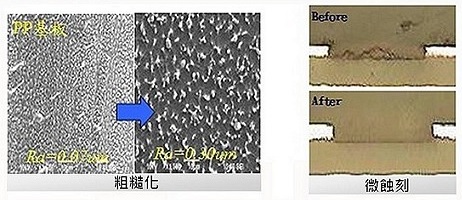

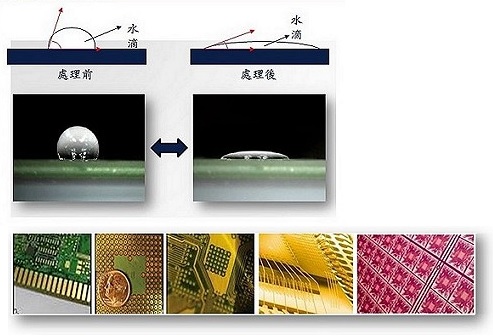

Surface modification/Surface cleaning/Roughening

產品說明

- Plasma dry etching

- Etching material: Cu, Ti, Ta, Si, SiO2,Pd…(All kinds of metal)

- Etching material:PP,PR,PMMA,ABF,Epoxy…(All kinds of polymeric substance)

- substrate: Wafer, Si, Glass, PP, PMMA, Cu…(All kinds of substrate)

Equipment characteristic

- High-speed dry etching process

- High cooling capacity,Low substrate deformation

- High aspect ratio etching direction(low side etching)

- High Capacity、Low revolution cost

- Modulized design,Customization

- Substrate size:4”, 6”, 8”,16” x 20”, 20” x 24”

Product application category

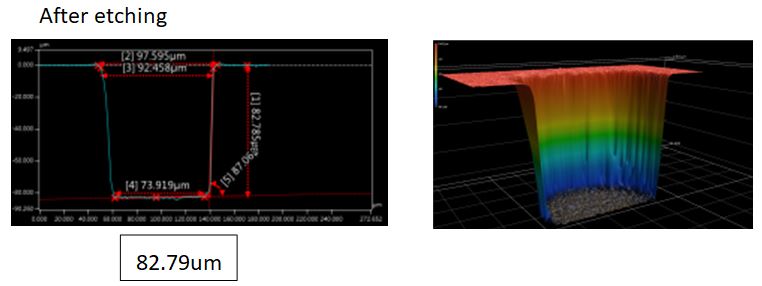

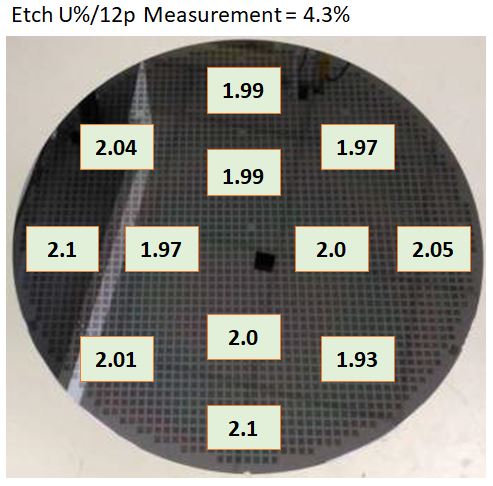

Silicon Wafer Etching Plasma/ Reactive Ion Etching Plasma

Product Description

- Plasma dry etching process(RIE)

- Etching material: Si, SiO2, Si₃N₄

- substrate: Wafer, Si, Glass

- Used Gases: O2、Ar、N₂、CF₄、SF₆、CHF₃

Equipment characteristic

-

High-speed dry etching process

- High cooling capacity,Low substrate deformation

- High aspect ratio etching direction(low side etching)

- High Capacity、Low revolution cost

- Modulized design,Customization

- Wafer size:8”, 12”

Product application category