- All

- EMI Coating

- AR Coating

- AF/AS Coating

- IC carrier (PBGA)

- Heat dissipating substrates

- LED industry

- Barrier layer

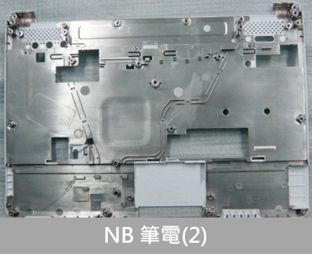

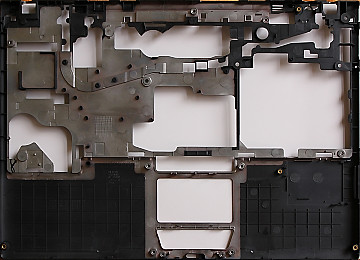

EMI Coating

Electromagnetic interference was confined within a plastic shell with a sputter-deposited metal coating. The metal coating was used as shielding to achieve “anti-electromagnetic interference.”

It is applicable to products requiring electromagnetic protection, such as cell phones, laptops, microchip packing, GPS devices, MEMS, film antenna, radio devices and others.

It is applicable to products requiring electromagnetic protection, such as cell phones, laptops, microchip packing, GPS devices, MEMS, film antenna, radio devices and others.

Product application category

AR Coating

Optical interference principles are used to deposit multiple layers of coating on the surface of substrate to increase the penetration of substrate, decrease reflection and enhance images; it is applicable to lenses, display panels, cell phone screens and others made of transparent materials such as glass, PET, PC and more.

Product application category

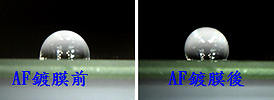

AF/AS Coating

Applicable to glass, PET, PC and other transparent materials; widely used in products such as lens covers, touch screens, cell phone screens and more.

Contact angle before coating: 40~50o (glass); contact angle after coating: >110o (glass)

Product application category

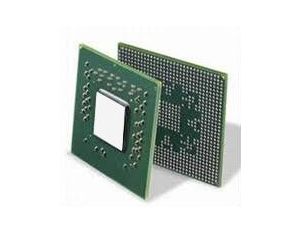

IC carrier (PBGA)

Vacuum sputtering technique is used on the surface and inside (pores) of substrate to create a coating of conductive film, which completes the circuit with components made in associated processes.

Applicable to (PBGA/CSP/FCCSP) IC carriers in the design process of high-density conductors with no electroplating.

Product application category

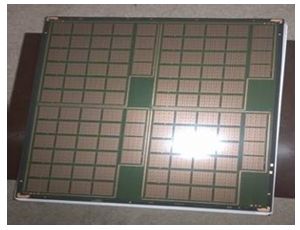

Heat dissipating substrates

A coating of conductive film is deposited on non-conductive insulation layer or ceramic material to complete the circuit with components made in associated processes; applicable to heat dissipating substrates in high power/high wattage LED and solar panels (aluminum/ceramics).

Product application category

LED industry

Vacuum sputtering is used to deposit highly reflective metal on LED focus lamps to prevent scattering and leaking from the back and sides; the illumination can be increased significantly with the help of focus lamp angle and secondary optical effects.

Applicable to flash light on cell phones, bicycle lamps, hand-held devices, and other lighting products.

Applicable to flash light on cell phones, bicycle lamps, hand-held devices, and other lighting products.

Product application category

Barrier layer

A barrier layer is added between two different media (substrate and coating) to prevent interference between media.

Product application category